Holding the right levels of inventory, closest to the point of demand generation is the key to deliver highest levels of Demand Fulfillment and Customer Satisfaction.

This model example is showcase the art of the possible. Our configurable Application found here

However, defining the right inventory levels and being able to consistently meet that target is difficult, especially in a Multi-Echelon Distribution Network where multiple product families are procured from multiple suppliers and are stored across multiple locations. One key aspect that separates highly successful distribution networks from others is their ability to predict demand and supply at forward locations, and respond effectively by making the right allocations and transfers across the distribution network. Valizant’s Demand Driven Distribution app on Anaplan helps you achieve this capability more easily through its comprehensive design and ready to use technology.

Information

App Last Updated

March 15th, 2017

Size

810.6 MB

Language

English

App stats

Modules

39

Roles

1

Formulas

720

Reports

14

Complexity

Intermediate

Why Anaplan for Demand Driven Distribution ?

- Pull Driven Distribution Network that is more accurate

- Clear and Unified view of Supply Exceptions

- Drill down capability to any level of detail

- Fresh, precise information that can be acted on

Replace inefficient top-down Inventory Allocation methods with a pull driven process that is more realistic, responsive and accurate. Respond to market demand by positioning right levels of inventory at right locations. Improve customer satisfaction by recognizing exceptions before lead time.

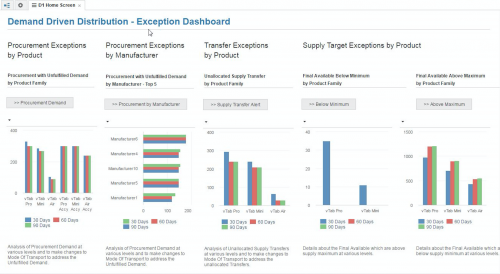

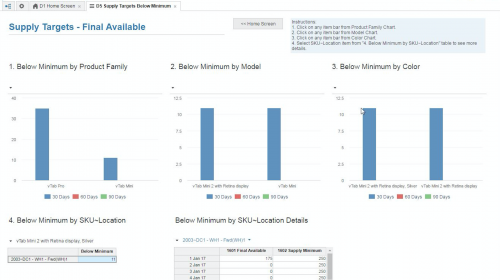

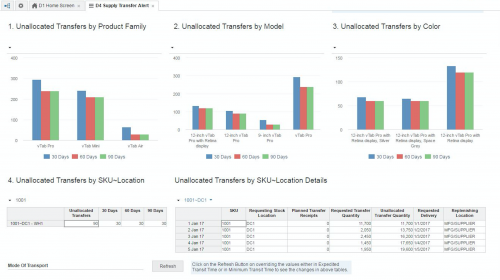

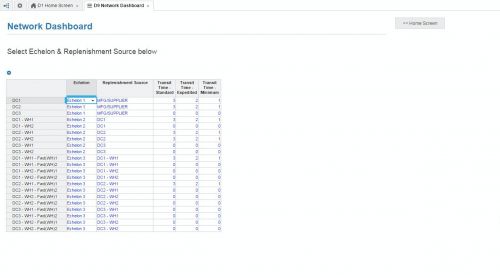

View Supply Exceptions by Product Family, Location, and Suppliers in a single dashboard. Review exceptions that have highest business impact in the short term and in the long term, for example over 30 day, 60 day and 90 day periods.

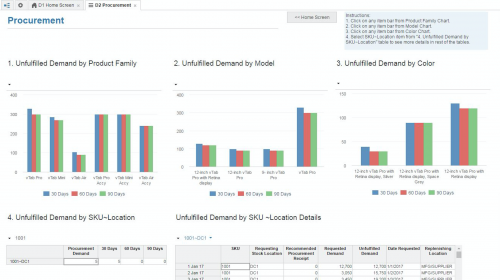

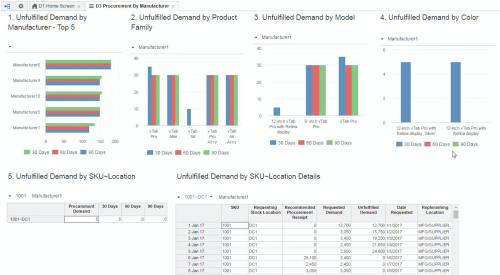

Uncover reasons of exceptions by going down to the details using drill down capability. View ERP level detailed information like Recommended Receipts versus Requests, Planned Transfers versus Requested Transfers, for Product SKUs, filtered by attributes like Color and by forwarding locations.

Tie your Supply Plan decisions to actual execution. Respond to exceptions by raising ERP requests like Transfer Orders, Purchase Orders, or by expediting shipping modes, right from the Valizant app on Anaplan. Review impact instantly when ERP data is updated.

Replace inefficient top-down Inventory Allocation methods with a pull driven process that is more realistic, responsive and accurate. Respond to market demand by positioning right levels of inventory at right locations. Improve customer satisfaction by recognizing exceptions before lead time.View Supply Exceptions by Product Family, Location, and Suppliers in a single dashboard. Review exceptions that have highest business impact in the short term and in the long term, for example over 30 day, 60 day and 90 day periods.

termsTitle