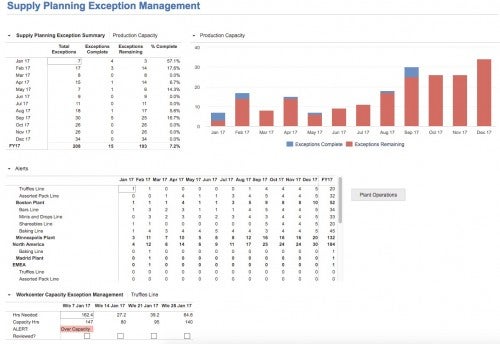

The Supply Planning app assists manufacturing organizations to visualize and plan their supply chains from Distribution Operations back to Production Planning.

Manage your supply chain by inventory, order shortage, and capacity exceptions. Use the calculated suggested order quantities by week or manually override to proactively account for high demand or supply shortages.

Information

App Last Updated

June 2nd, 2017

Size

2.98 GBs

Language

English

App stats

Modules

118

Roles

3

Formulas

542

Reports

11

Complexity

Advanced

Features

Exception Management

- DC Inventory Exceptions: below safety stock; greater then max inventory

- DC Capacity Exceptions

- Production Capacity Exceptions

- Order Shortage Exceptions

Distribution Center Demand

- Sales Orders: Open customer order quantities

- Forecast: Statistical forecast quantities by product and DC

- Distribution: Units ordered from one DC to another

- Dependent: Requirements needed to assemble specified finished goods within a DC

DC Operations/Netting

- Suggested weekly order requirements for each DC by finished good based on netting logic

- Ability to override system suggestion manually

- Days of Supply tracking

- Override safety inventory days manually

- View order shortages and expired inventory quantities over time

DC Capacity Analysis

- Analyze total DC capacity and DC required capacity based on pallet count

- Manually increase capacity to account for over capacity periods

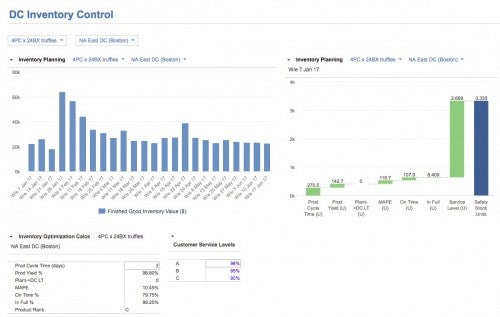

Inventory Optimization Analysis

- Set safety stock levels based on multiple parameters: customer service level, MAPE, Lead Time, Production Yield %, etc...

- Run a What-If Analysis view the safety stock impact by overriding parameters

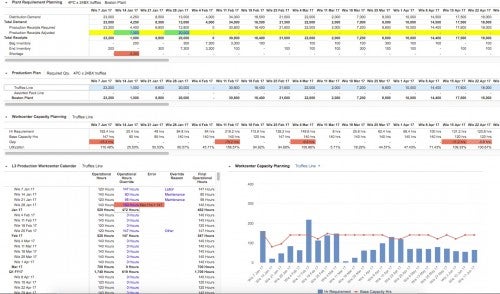

Production Planning

- Netted DC requirements dropped to supplying production plant and offset by transit lead time

- Product requirements disaggregated to appropriate production line

- Total production hours required calculated per item/work center run rates

- Work center weekly calendar with available hours and override capability

termsTitle